Support Team

Feedback:

support@nextpcb.com

Printed Circuit Board Assembly is an essential step in every PCB design and PCB manufacturing. Your consumer electronics would only function properly with a proper circuit board assembly. There is an urgent need to understand PCB Assembly and its steps.

Printed Circuit Board Assembly is putting together essential components on a fabricated circuit board to create a functional circuit board. The more components on the circuit board, the more complex the assembly process becomes.

NextPCB provides an ultimate guide to the step-by-step Printed Circuit Board Assembly process in this post. Also, it discusses the kinds of PCB mounting technology in the Assembly process and essential components that are common in PCB Assembly process.

The PCB industry is always dynamic in providing quality PCB Manufacturing and Assembly processes. When it comes to the Assembly process, there are two mounting technologies that PCB Manufacturers employ: Surface Mount Technology (SMT) and Through-Hole Technology (THT). Let’s examine each of these mounting technologies and their differences.

SMT is undoubtedly one of the best Printed Circuit Board Assembly technologies in the PCB Industry. With surface mount Technology, the manufacturing process of Small-sized yet functional PCBs is achievable.

Also, the Surface Mount Technology allows small components like resistors, diodes, and integrated circuits carefully mount on the surface of the PCB. Surface mount technology is low-cost, faster, and offers higher accuracy in the production process.

However, Surface Mount Technology has a significant drawback. It is not ideal for circuits prone to frequent vibrations and stress, which would lead to the components falling off the circuit boards.

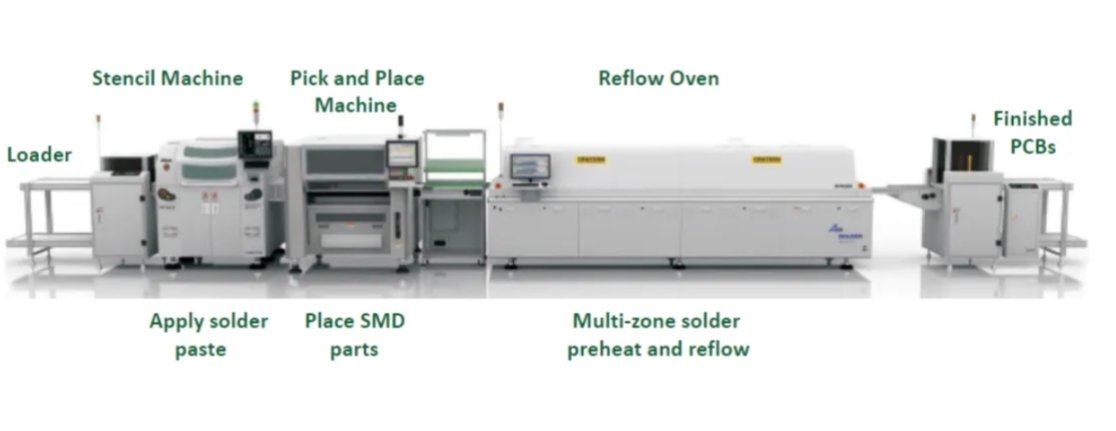

The Assembly Process involved in Surface Mount Technology includes:

Through-Hole technology shines excellently in circuits subjected to frequent mechanical stress and vibrations. This technology requires precise drilling of holes on the Printed Circuit Board for components with leads firmly attached.

Through-Hole Technology is great for large components such as capacitors, relays, plug connectors, and electromechanical coils that fit into the board. These components use the holes to pass signals from one side of the board to the other.

However, This Technology is more expensive than SMT. It is a less reliable method as the holes need to be precise, or the assembly process could lead to design and functional errors during testing.

The Assembly process involved in the Through-Hole Technology includes:

Printed Circuit Boards are the heart of all electronic devices regardless of their operations and functions. As such, there is a need to carefully follow the outlined steps involved in the PCB Assembly Process.

Printed Circuit Board Assembly takes place after PCB Manufacturing; that is, a bare circuit before placing any component on it. The circuit board will have the required layers (single, Double-sided, multi-layer) and copper traces.

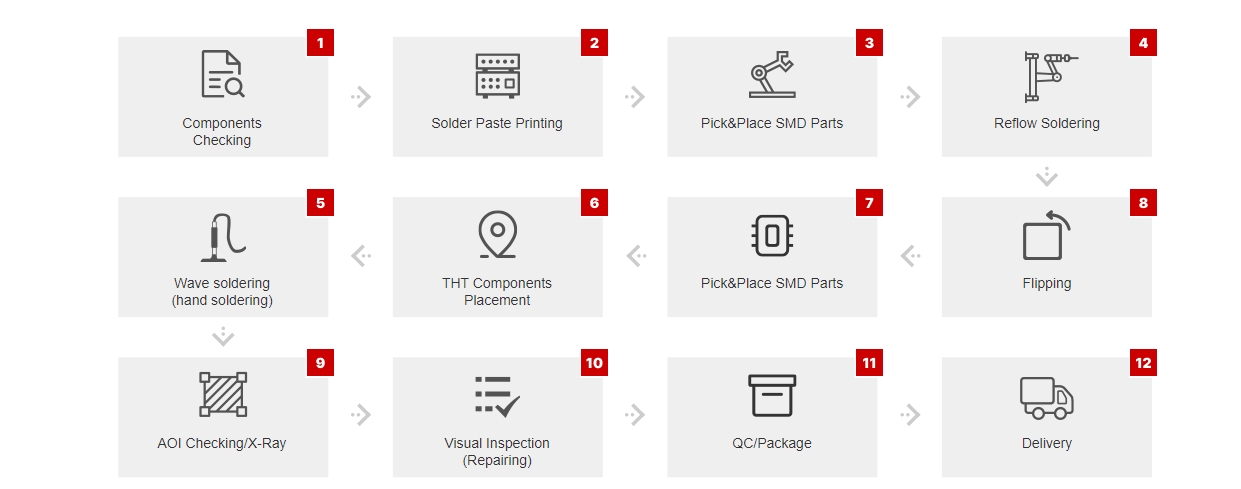

pcb assembly process flow chart

Here are the required steps in the PCB Assembly Process:

The first PCB assembly process is solder paste application to the bare circuit board. This solder pasting aims to fill the circuit board with enough paste to fix electrical components quickly.

This process requires a stainless-steel stencil with the same shape, width, and size as the bare Printed Circuit Board. It is usually made of brass or common material, stainless steel.

The Stencil follows the set PCB design and has holes that will be filled with solder paste. This Stencil is then carefully fit on top of the bare circuit board, which covers areas that do not require solder paste.

After fitting the stencil on the circuit board, a solder paste applicator will distribute the solder paste evenly to the uncovered spaces. Then, the PCB assembly team will check if the solder paste evenly distributes on the circuit board via the Stencil.

For a double-sided circuit board, each side will have a stencil for even distribution of solder paste

Once the solder paste evenly distributes on the bare Printed Circuit Boards, the next step is picking and placing components on the circuit board. The required components undergo thorough inspections to check for defects or malfunctions before placement.

With advanced technology, this process is automated as Pick & Place machines will pick specific components and place them on their required paste. The automation ensures maximum efficiency and accuracy.

Upon placement of the components, the Circuit board assembly team will inspect the PCBs of the solder paste enough to hold the components in place. This process takes place several times to ensure that no component is loose on the circuit board.

For a double-sided PCB, the step is the same; the components fixed on one side will undergo thorough checks then the other side with its components will also go through similar inspections.

Some pick-and-place machines put small amounts of adhesive to secure the components further. Yet, it can be disadvantageous, especially if the components’ placement is misaligned from the original PCB design specification.

Regardless of the Assembly technology, this pick-and-place process is necessary and automated for better accuracy.

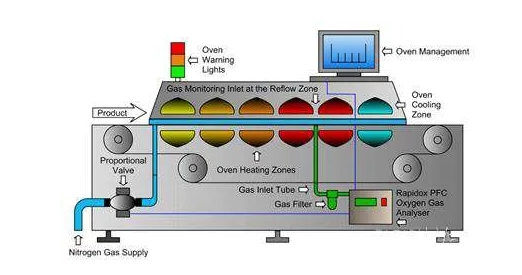

The third step is Reflow Soldering. This process involves passing the circuit board through varying temperatures to melt and resolve the solder.

The circuit boards with their required components will pass through an industrial oven or furnace that heats the solder and then melts it to ensure a proper connection between the components and the board.

The PCB temperature could be as high as 245℃. A primary concern regarding this process is that the components affixed to the circuit boards must withstand these high temperatures for some time.

After, the printed circuit boards moves to an industrial cooler, which lowers the circuit board’s temperature and solidifies the liquid solder paste, further fixing the components on the board.

For double-sided circuit boards, it is necessary to use a unique adhesive to hold the other side components in place to prevent them from falling off. This process takes about ten minutes (usually less).

Reflow soldering working principle diagram

After the Printed Circuit Board is at room temperature, it undergoes two inspections.

The manual inspection could cause eye fatigue and strain, especially if a circuit board holds hundreds of components.

The x-ray inspection, however, enables easy detection as the machine captures an image of the solder joints to determine the quality of the solder joints is comparable to industry standards. Also, x-ray inspection can help identify if the solder past is insufficient, there are misaligned components, or there is an incomplete reflow process.

The first final stage of the Printed Circuit Board Assembly Process is the final inspection. The final inspection ensures that the circuit board, the solder paste points, and the components conform with the desired PCB specifications. Also, thorough cleaning of the printed circuit boards to remove debris or excess solder.

After the final inspection, functional tests are necessary to test the Printed Circuit Boards and their soldered components for functionality.

Employing Automated Optical Inspection can subject your PCB to real-world testing via simulations to ensure that it provides quality operations to consumers in electronic devices.

Also, in-circuit Testing is another intensive test that ensures that each component is functional and offer no errors on the Printed Circuit Boards. However, the in-circuit test is time-consuming and could add to the manufacturing costs. Still, clients can request this test for their PCB, fully aware that they will pay the extra charges.

The functional test determines the success or failure rate of the Printed Circuit Board assembly. Hence, a Printed Circuit Board will not get to packaging and shipment if it fails in any required functional tests.

Moisture is threatening PCB electronics assembly. It may seep into the PCB manufacturing process or during the assembly phase. In any case, moisture can affect the lifespan of the circuit board and its components due to condensation.

This phenomenon, condensation, occurs when these circuit boards are in containers with lower temperatures than the surroundings. To ensure quality PC Board Assembly Processes, practical anti-moisture evaluation should be available during components’ selection.

It is a known fact that PCB electronic devices are widely used in various sectors such as automotive, medical, industrial, and transportation. These printed circuit boards operate in harsh conditions, especially high temperatures. These high temperatures could prevent the components from functioning correctly.

PCB Manufacturers must note the effects of high temperatures on their electronics. Also, they can specify the temperature range of these products during packaging and shipping.

Due to advancements in PCB trends, thermal-resistant materials are employed in designing active and passive PCB components to ensure they operate within temperature ranges in their respective industry.

As earlier stated, PCBs are useful in various applications and sectors, often requiring operating them at high vibrations or frequencies. It is noteworthy that high vibrations or shocks could break the circuit board hence the circuitry and mechanical components found within the printed circuit board.

The through-hole technology effectively deals with PCBs often associated with shocks and high vibrations to combat this problem. This PCB assembly technology ensures that components are permanently fixed into the circuit board.

Due to rapid changes in modern electronic technology, components have limited lifespans, becoming obsolete when new components hit the PCB market. These old components become obsolete and have reached their End of Life stages.

When components become obsolete, there is an increased chance that the PCB starts to malfunction due to mechanical and physical stress, thereby reducing its efficiency and reliability. Also, when new PCB technologies arise, these obsolete components may have difficulty meeting the new performance requirements and hence have a greater chance of failure.

To ensure consumers know their PCB expiration date, PCB manufacturers must carefully explain to them the new alternative devices to opt for when their PCB exceeds the expiry date.

Why is PCB Assembly Expensive and How Can You Reduce Costs?

PCB assembly can be costly due to factors like the price of high-quality components, the labor involved, and the advanced equipment required for production and testing. Low-volume runs also drive up per-unit costs, and specialized processes like prototyping and customization add to the expense.

However, there are ways to cut down on these costs. By optimizing your design for manufacturability (DFM), using standard components, increasing production volume, and choosing cost-effective manufacturers, you can save significantly. Additionally, panelization, reducing board complexity, and establishing long-term partnerships with manufacturers can lead to more efficient production and lower costs.

1. Optimize Design for Manufacturability (DFM):

One of the most effective ways to reduce PCB assembly costs is by simplifying the PCB layout and designing the board for efficient manufacturing. This includes avoiding unnecessary layers, minimizing complex routing, and using standardized footprints for components. DFM ensures that your design is easier to assemble, reducing the risk of errors during production and lowering overall costs. Consulting with your manufacturer during the design phase can help identify areas for optimization.

2. Consolidate Orders and Increase Production Volume:

Manufacturing costs tend to decrease as production volume increases. This is because setup costs, machine time, and labor can be spread over a larger number of units. By consolidating smaller orders into larger batches, or by planning for higher production volumes, you can take advantage of economies of scale. For businesses that anticipate frequent PCB orders, building in some forecasting and increasing order sizes can be a cost-effective strategy.

3. Use Standard Components:

Custom or specialized components can be more expensive to source and may lead to longer lead times. By opting for standard, readily available parts, you not only save money but also speed up production. Components that are widely used across industries are often cheaper due to their high availability, and manufacturers are more likely to have experience working with them, which can reduce the chances of assembly issues.

4. Panelization:

Panelization is a technique where multiple PCBs are grouped together on a single panel during production. This allows for more efficient use of materials and reduces the number of machine setups needed. After the assembly process, individual PCBs can be separated from the panel. This method reduces production time, material waste, and overall costs. It’s particularly useful for smaller boards, as manufacturers can process many boards at once.

5. Outsource to Cost-Effective Regions:

Outsourcing PCB assembly to manufacturers in regions with lower labor costs can significantly reduce expenses. However, it's essential to ensure that the manufacturer maintains high-quality standards and adheres to relevant certifications such as ISO or IPC standards. Balancing cost with quality is crucial, so carefully vetting potential suppliers is recommended.

6. Reduce Board Complexity:

The complexity of a PCB can directly impact the cost. More layers, intricate routing, and specialized features like controlled impedance or fine-pitch components all add to the overall expense. Simplifying your design by reducing the number of layers or avoiding unnecessarily complex routing can help keep costs down. Focus on essential features and prioritize functionality over excessive complexity when possible.

7. Establish Long-Term Partnerships:

Building long-term relationships with PCB assembly manufacturers can result in better pricing over time. Many manufacturers offer discounts for returning customers, especially if they expect consistent, forecastable orders. These partnerships can also lead to better communication, more personalized service, and faster turnaround times, which can be beneficial for long-term cost management.

Conclusion:

While PCB assembly can be expensive, following these strategies can help you reduce costs without sacrificing quality. Design optimization, using standard components, increasing production volumes, panelization, outsourcing, reducing complexity, and building long-term partnerships with reliable manufacturers are key factors to achieving more cost-effective PCB assembly.

At NextPCB, we are committed to offering a comprehensive range of services from PCB designing, manufacturing, PCB Assembly, and more. By developing PCBs with state-of-the-art machines and equipment, you can receive high-quality PCBs suited to your needs.

If you have any information regarding some PCB services and solutions, kindly quote now and enjoy an unbeatable customer experience from us.

Still, need help? Contact Us: support@nextpcb.com

Need a PCB or PCBA quote? Quote now

|

Dimensions: (mm) |

|

|

Quantity: (pcs) |

|

|

Layers: |

Thickness: |

|

|

|